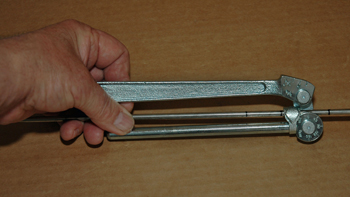

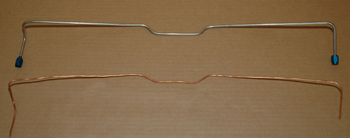

This is the part where patience is critical and it might take a few mistakes before you get quick at bending lines that twist multiple directions in one length of tubing. This makes for a perfect bend length calculation every time.

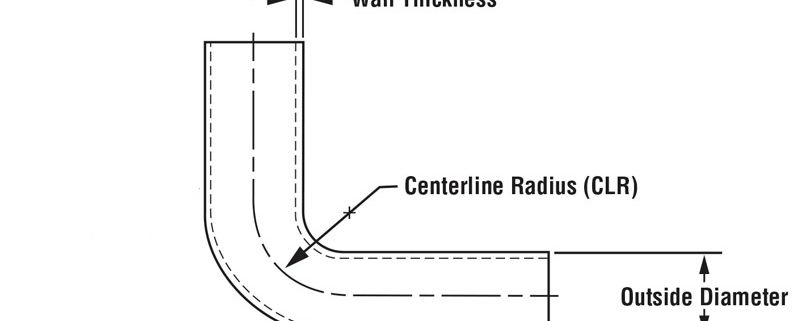

Press Brake Wikipedia

Brake line bending instructions. The most important factor that you need to keep in mind when bending brake lines dont forget the flares and fittings. With your new line ready for installation the last piece is to blow out the line with compressed air like from a brake cleaner to ensure that no debris is left in the line. Figure the length of tube that is needed to meet your offset requirements x in dimension diagram from table. Now place your brakeline in your bender lining up your mark at 0 degrees and make the bend. Line up the mark from step 3 with the support on the tube bender. Even seasoned pros sometimes to forget to slide the fitting all the way to the flare before bending the line which means you have to either straighten the line or cut and reflare the line.

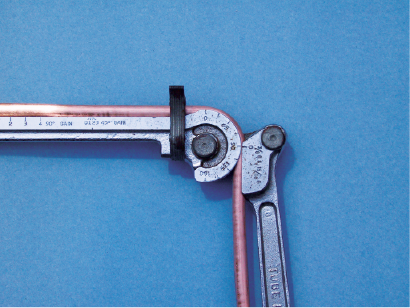

After flaring the first section of line and making the slight bend as the right rear wheel brake cylinder he proceeded to mark the locations for the bends needed to follow the contour of the. See all 2 photos. Brake line bending and flaring tudor tales. Measure and mark a spot 25 from the location marked in step 2. Despite a bit of slow progress on the tudor solely on my part things are. Make sure you use the correct mold for the size tube you are using.

How to make brake lines sae and din flaring and bending cunifer and copper. The dutch garage 12811 views. Rob fortier writer eric black illustrator. Determine the total amount of offset required dimension y in diagram and angle of offset. Return from brakeline bending tip to hot rod brakes. Now with your marker transfer the line on your template line to the actual line that you are using for your brakeline.

Line up the brake line with the hole it must pass through and mark the location on the tube. Bending brake lines by jim clark step 1.