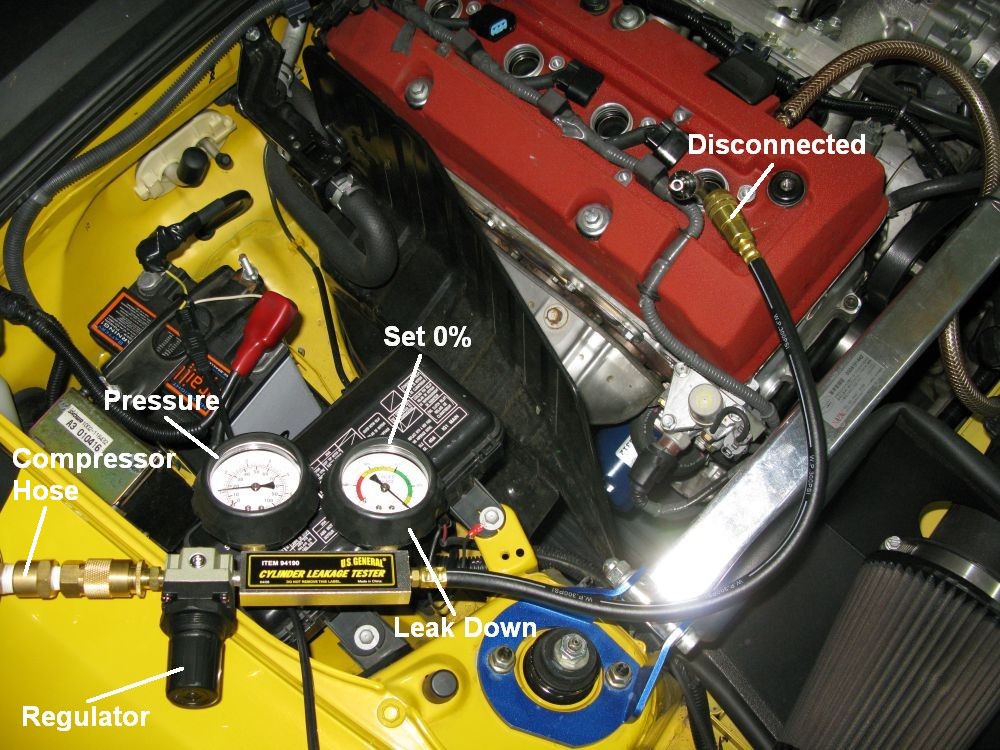

A leak down test is performed with a special gauge and manifold set. A cylinder leak down test requires the removal of all the spark plugs.

Compression And Leak Down Testing

Compression leak down test. They both test the sealing ability of the combustion chamber but the leak down can tell you how much is leaking and where its going. Use the spark plug socket and ratchet to remove the no. The compression test works by spinning the engine through its cycles with the compression tester in. Leakdown and compression test engine compression. A leak down test works by putting air pressure into the cylinder and the gauge measures the amount of. A 91 compression ratio cylinder is.

Always make sure to test cylinder leakage with the piston at the top of the cylinder. A leak down test can tell you quite a bit more about an engines mechanical health than a compression test can. Pressurized air is supplied to each cylinder and in moments displays a rate of leakage measure from 0 to 100. A leak down test. An engine leakdown test is a compression test in reverse. Insert a large screwdriver or long thin dowel into the plug.

Compression testing is a crude form of leak down testing which also includes effects due to compression ratio valve timing cranking speed and other factors. A threaded coupling is screwed into a spark plug hole. A compression test is exactly as it sounds it measures the amount of pressure that an engine can. Remove the plug boot from the no. Put manual transmissions in gear and firmly set the parking brake to keep the compressed air from turning the engine. Instead of measuring the engines ability to create pressure compressed air is introduced into the cylinder through the spark plug hole.

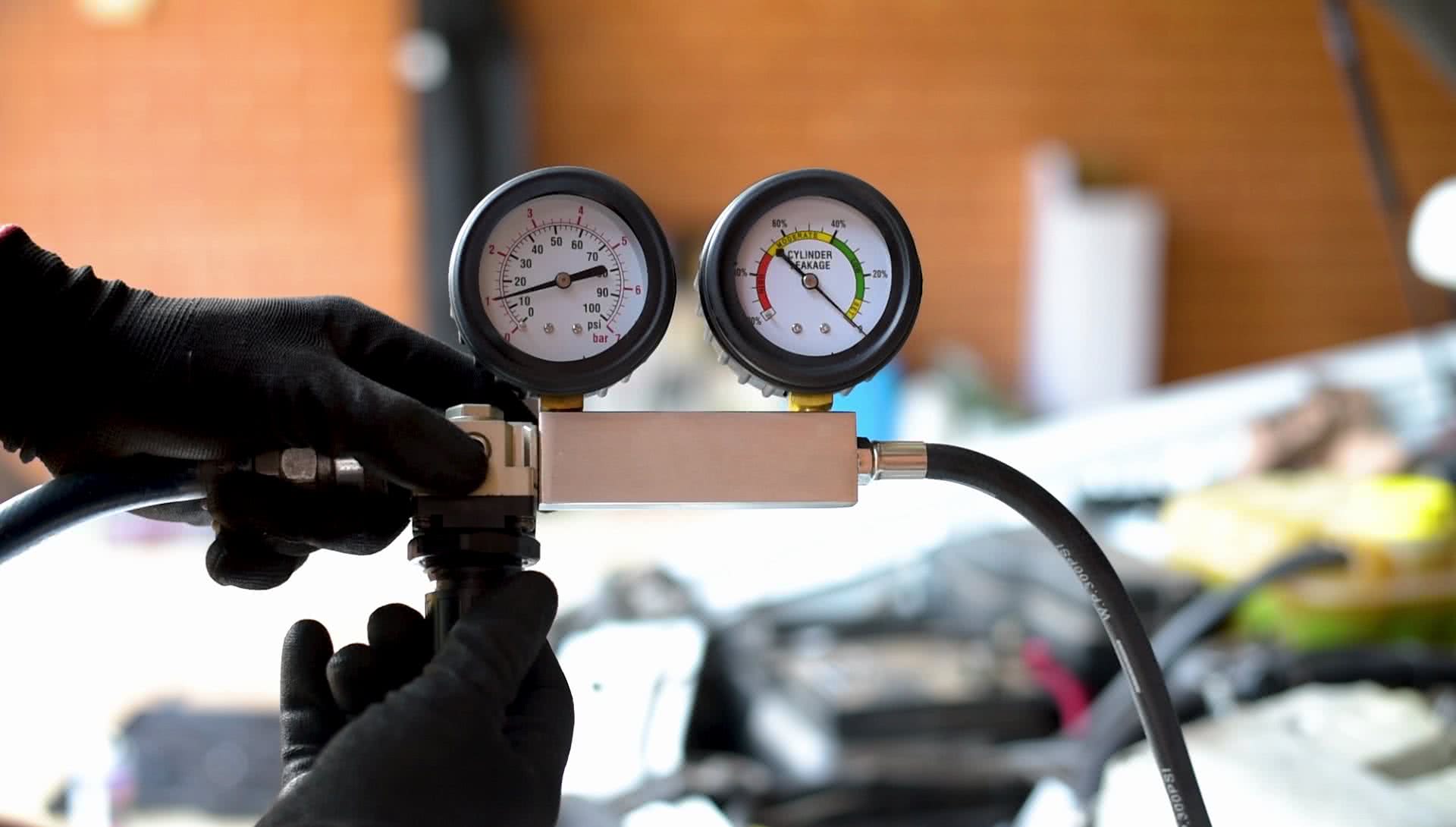

Compressed air or nitrogen is fed into the gauge and the gauge is calibrated against a zero reference no air leakage. Pros and cons of compression testing. This cylinder leak down tester gauges leak down tests more accurately than standard compression tests. Browse recommended tools supplies for this build. Compression tests should normally be done with all spark plugs removed to maximize cranking speed. Compression test a compression test.

The crankshaft is then turned so that each piston is at top dead centre. Compressed air 80 to 90 psi is then fed into the cylinder. This is where the greatest cylinder wear occurs. It does little good to measure leakage with the piston at. Atmospheric pressure at sea level is approximately 147 psi. It consists of a calibrated pressure gauge and a pressure regulator and adapters to connect it to the spark plug hole.