The lip sealing ring ensures quick and efficient jointing of the pipe system while providing a tight seal in case of both pressure and vacuum. Nbr epdm what is nbr and what are the applications.

The Vulcanization Characteristics And Physical Properties Of

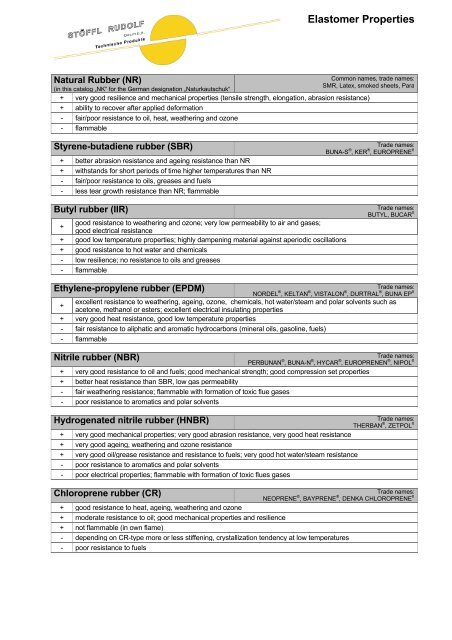

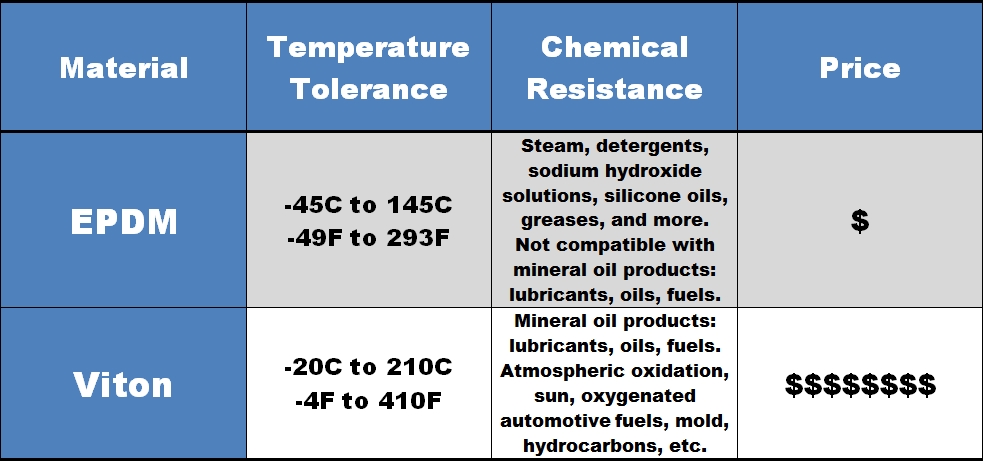

Epdm and nbr difference. Animal and vegetable oils ozone strong and oxidizing chemicals. Epdm is a synthetically produced ethylenepropylene rubber and an elastomer which is most widely used in both general purpose and special purpose applications. Epdm has a lower compression set a higher tensile strength a better resistance to heat aging and high weathering resistance. Nbr is an unsaturated carbon rubber which is polymer made from acrylonitrile and butadiene. Nbr has a better oil resistant compared with epdm but epdm has a good wear resistance aging resistant and heat resisting. The acrylonitrile amount from low to high and oil resistant will enhance and cold resistance will decline during the producing.

There are 10 material properties with values for both materials. For each property being compared the top bar is epdm rubber and the bottom bar is sbr rubber. Epdm beats sbr in tensile strength and resistance to heat aging and weathering. Both epdm rubber and sbr rubber are thermoset elastomers rubber. Poor resistance to petroleum based fluids. Nitrile butadiene 30 f 250 f.

Properties with values for just one material 2 in this case are not shown. A lip sealing ring constitutes the seal between socket an spigot end. One attraction to nbr is its stability in low temperatures with the ability to survive extreme cold of 30c 22f which epdm and silicone cant match. Synthetic rubber comes in nearly a dozen major types with differing properties for various applications. The strength of nbr lies in its moderate costs and good resistance to swelling caused by hydrocarbons or acids. Ethylene propylene 40 f 300 f.

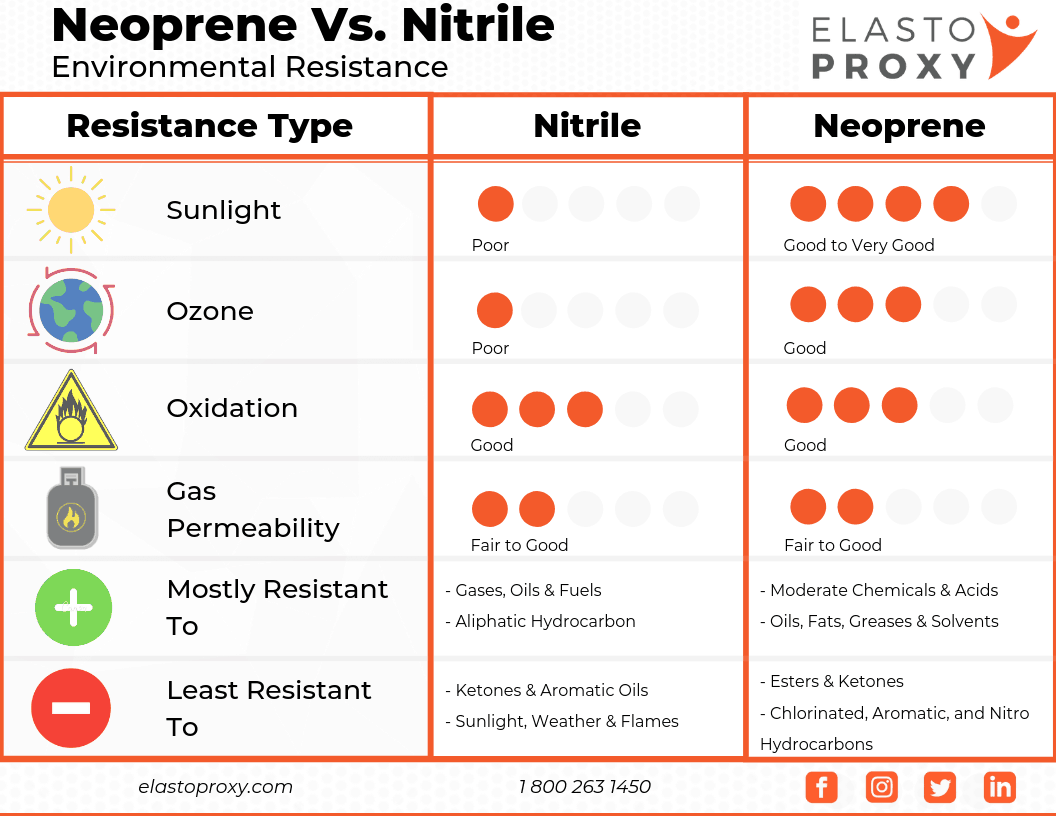

Nitrile is king of elastomers when it comes to oil and fuel resistance. What is the difference between neoprene and epdm. Nbr stands for nitrile butadiene rubber. Mineral oils and solvents aromatic hydrocarbons. Blücher sealing rings are available in three different rubber qualities epdm nbr and fpm. Nitrile butadiene rubber nbr stands alone as the most oil and fuel resistant elastomer.

However an sbr product will have a much better resistance to abrasions than an epdm product would. Nitrile butadiene rubber nbr. It is incompatible with petroleum oil and gasoline but it is compatible with alcohols ethanol methanol and nitromethane water coolants both ethylene and propylene glycol and glycol based brake fluid. Two common synthetic rubber compounds are known as epdm and nitrile rubber. It is a synthetic rubber copolymer of acrylonitrile and buta diene. Epdm is known as m class rubber since it has saturated chains of polymethylene.

Epdm while nbr and fkm have similar chemical resistance epdm is completely different. The biggest differences between these two rubber products lie in their resistance to petroleum based fuel and lubrication products and their resistance to weathering. Epdm is usually made into water pipe. Excellent ozone chemical and aging resistance. Moreover epdm shows excellent environmental and chemical resistant properties.