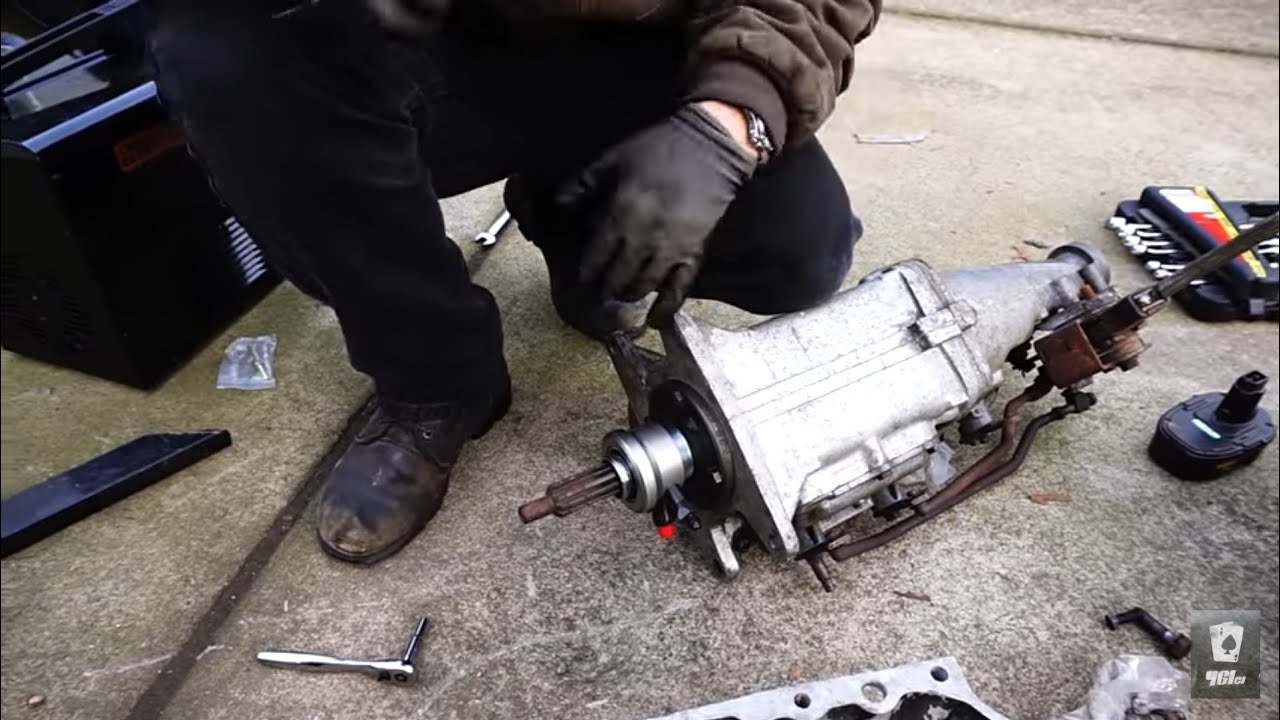

A throwout bearing is a part of an automotive clutch system that temporarily disengages the engine from the manual transmission while shifting. Just like wheel bearings allow movement of the spinning wheel hub around the non moving spindle the throwout bearing is the component that comes between the clutch pressure plate which is.

How To Replace A Throw Out Bearing Slave Cylinder In 3 Hours

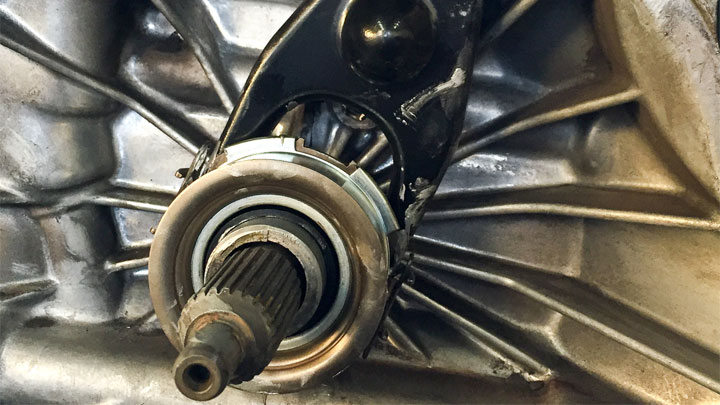

How does a hydraulic throwout bearing work. This redesigned new. The problem comes when the throwout bearing is too far from the clutchs fingers then you are shifting gears when the clutch isnt. Typically this hydraulic conversion offers easier pedal effort over a mechanical release bearing. The throwout bearing is used to activate the clutch. Our bearing kits offer full adjustability providing an easy setup with most single or dual disc clutches along. A jeep internal hydraulic throwout bearing common in yj wranglers and xj cherokees between 1987 1994.

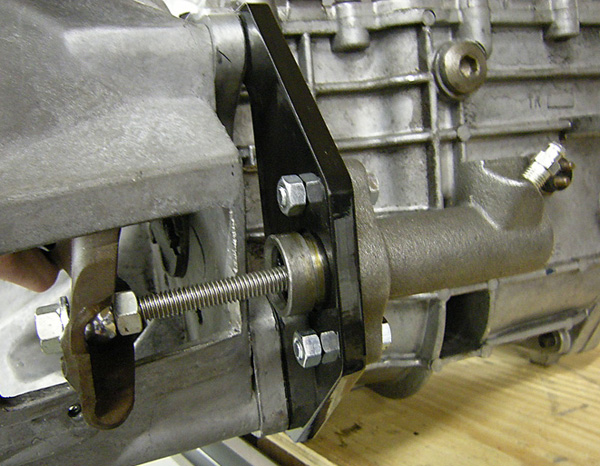

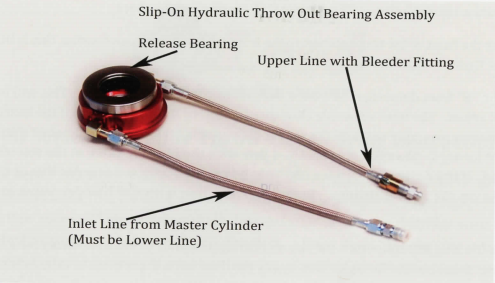

When you depress the clutch pedal the throwout bearing extends pressing in on the clutch fingers. This design combines the piston and bearing into one unit eliminating the pivot fork or release arm and separate throwout bearing. Hays offers upgraded release bearing kits for your favorite factory hydraulic equipped car along with applications to convert from a mechanical style to hydraulic style release bearing. Stock clutch hydraulic throwout bearing for stock style 3 speed and 4 speed chevy clutches only. Install simply by replacing one bolt from the front of the transmission with one of the provided studs then shim to fit. They are innovative in design but have gained notoriety for leak failures.

Using an adjustable master cylinder allows more fluid displacement to move the bearing which in turn moves the fingers of the clutch further. This is especially true with the hydraulic throwout bearing. It is a thrust bearing with the inner race attached to the clutch throw out arm and the outer race contacting the clutch de actuation fingers. This eliminates the need for complicated mechanical linkage as the bearing operates on hydraulic pressure developed by a master cylinder. Use 34 bore master cylinderthis bearing is made much smaller than the racing version so that it will fit behind the thicker stock style clutches. It translates a linear thrust force from the clutch pedal to the spinning clutch plate assembly mounted to the flywheel.

After fabricating a mount for the master cylinder all you need to do is route hydraulic lines to the release bearing.