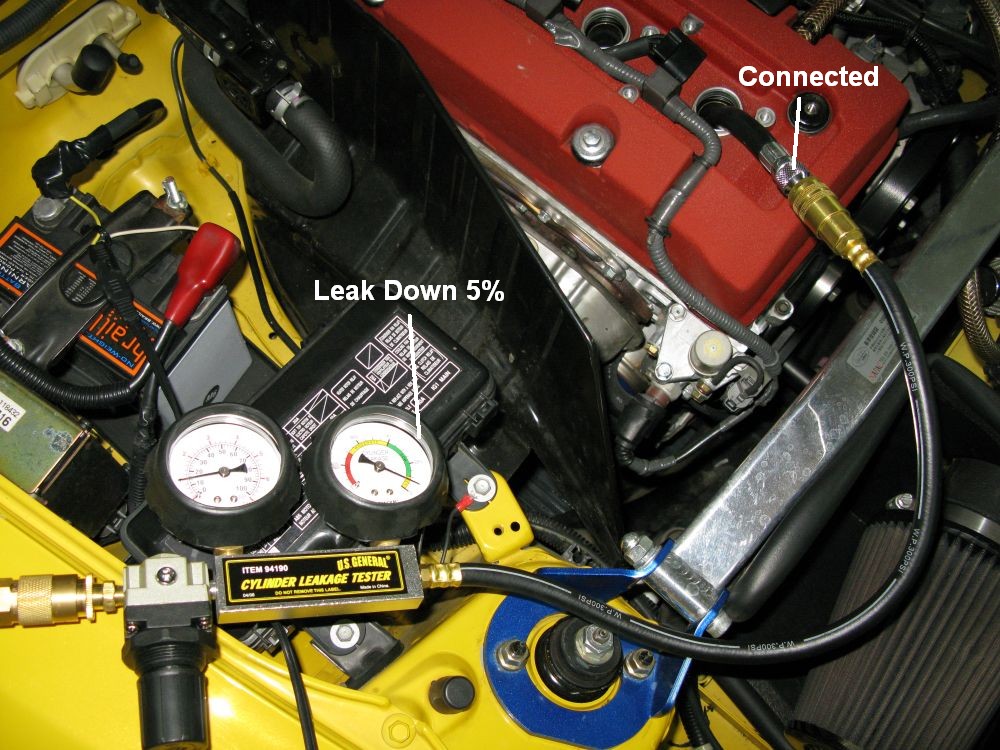

Performed a cylinder leakage or leak down test after a cylinder balance and a cylinder pressure test has verified a problem with the cylinder. It shows the percentage of leakage and pinpoints the part causing the compression leak.

Cylinder Tester Detector Engine Compression Leak Down Test Gauges Set Amp Red Case

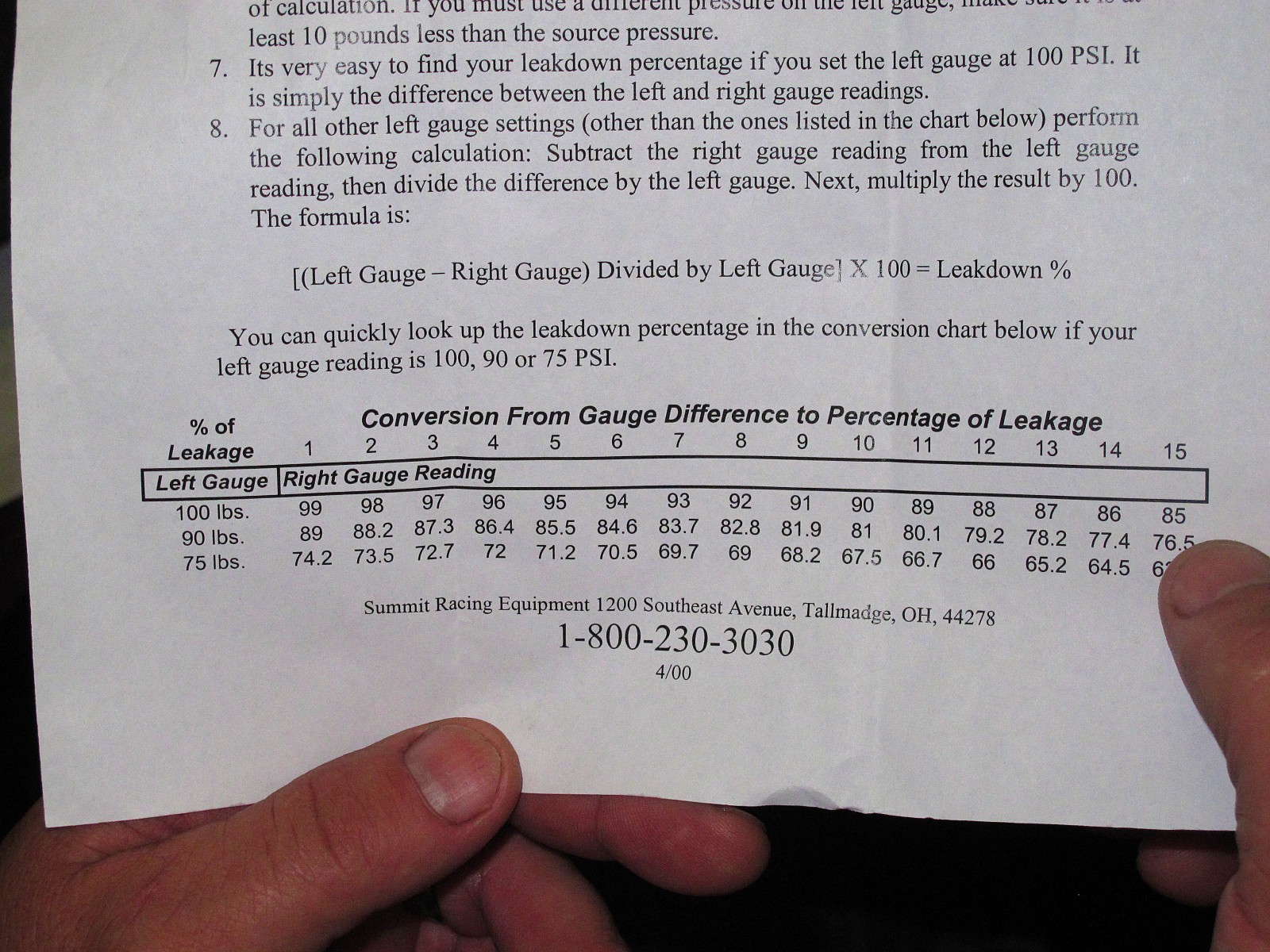

How much is a leak down test. Today its common practice to use a cylinder leakdown gauge to evaluate how well each cylinder performs in retaining pressure. A leak down test uses a set of gauges and pressurizes the cylinder with air and measures how much of that air is escaping. Consequently good cylinder leakdown readings should be below 5 8. The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder. Remove the spark plug and place the problem cylinder at tdc top dead center of the compression stroke. The cylinder leak down test reading is expressed in a percentage.

The process is simple enough pump a measured amount of air pressure. A leak down test also includes putting a pressure gauge into each cylinder in the engine though in this instance it is a leak down test device that is inserted with a display. A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke in which both intake and exhaust valves are closed. Then using a similar type of connector as the compression test we fill the cylinder with pressure. A leak down test is a compression test in reverse. As we outlined above a compression test is all about measuring the pressure that the engine can generate itself.

This procedure is different and usually more accurate than a compression test. A leak down test is one way a mechanic can find whether an engine has an internal problem instead of something external like a bad spark plug. The leak down test measures pressure loss inside a cylinder.