Superior essex copper cables outside plant and premises. Step by step instructions how to make male female jumper wires.

Wire Wikipedia

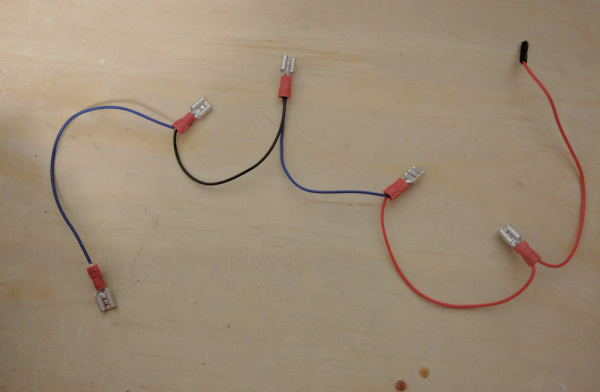

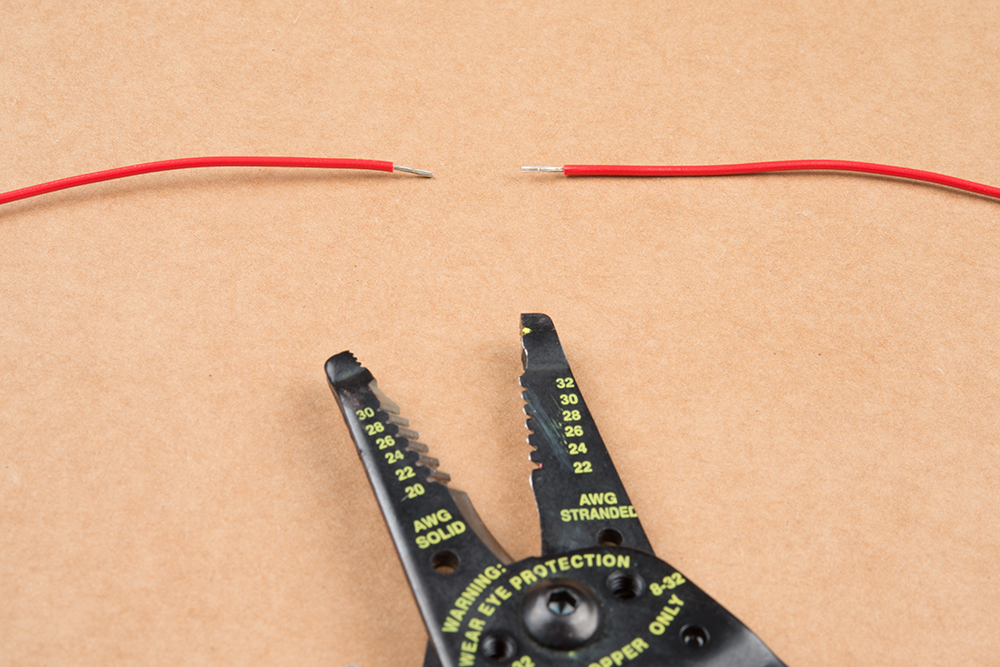

How to make wires. Ready to get coiled. Gather up all the parts. General cable how wire cable is made video duration. Heat shrink cable joint 11kv 3 core xlpe epr high voltage cable joints duration. For all but the smallest and largest connectors this is usually about 12 to 58 in. Feed the wire through the die and grab it with a pair of pincers on the exit side of the die.

Some heat shrink some wire wire cutters soldering iron male header pins. Start by stripping the ends of the wires. The drum will rotate pulling the wire through the die and onto the drum. Add tip ask question comment download. Attach the end of the wire to the drum with a clamp or vice and turn the drum on. First gather up all the parts.

Then arrange the wires parallel to each other with their ends aligned. Turn just any straight wire into a coiled one in under 10 minutes all you need is a heat gun and a few simple tricks that ill share to get the best results. Electric wire and cable manufacturing plant wire making business idea in hindi duration. Pull enough wire through the die to wrap it 2 or 3 times around a vertical drum. Check the label on the connector package for the length of bare wire to expose. Making your own coiled wires is super easy and will work on almost any type of stranded wire with a vinyl jacket.

Add tip ask question comment download. Unbox factory 533037 views.

/Electrical-Junction-Box-522663740-5794cf3f3df78c1734a322ed.jpg)