A threaded coupling is screwed into a spark plug hole. If the compression is low in a cylinder its time to find out why.

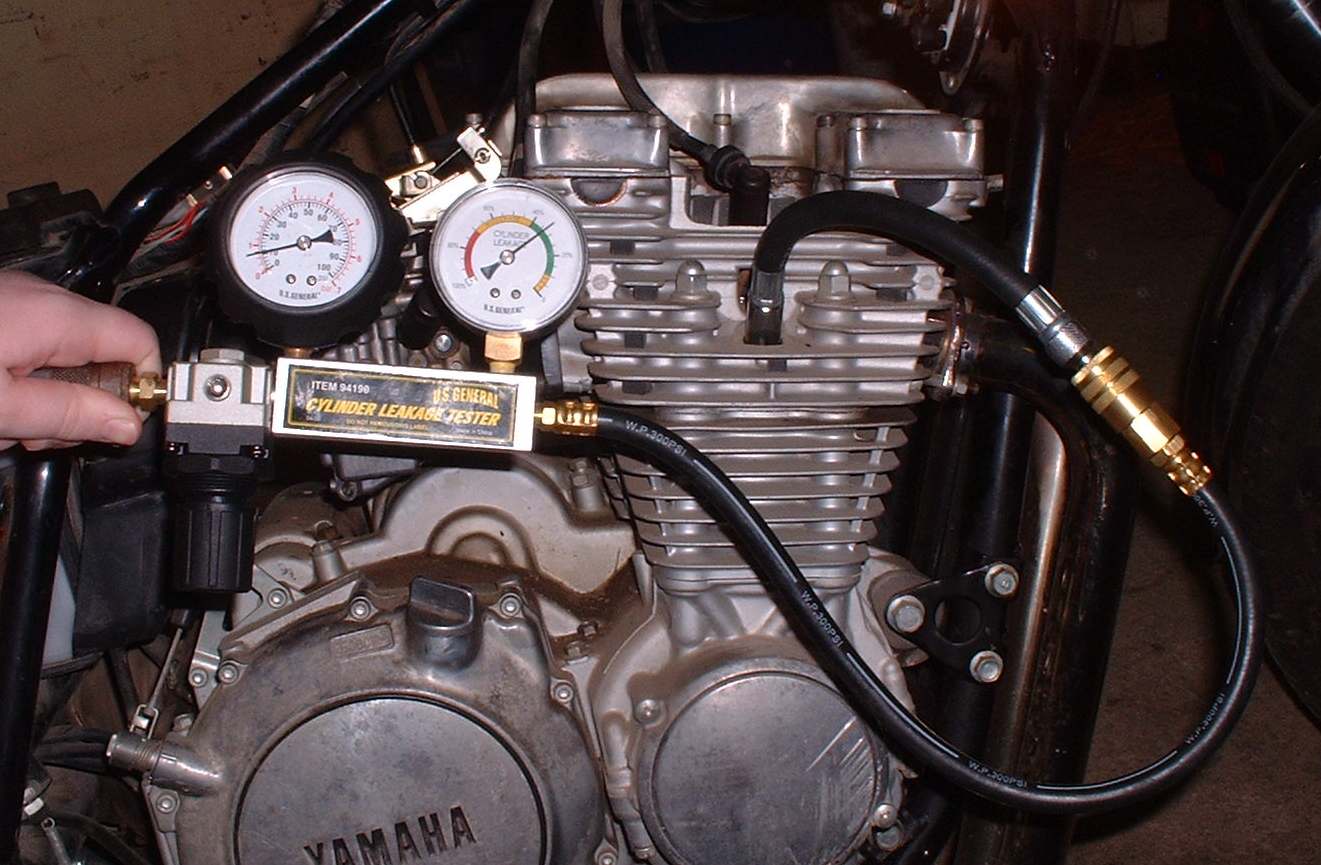

Dual Gauge Leak Down Tester

How to use a leak down tester. I wasnt able to get the tester to work correctly using the instructions provided with the tester so i made one. Figure out which spark plug adapter works best and connect the gauge into the hole. Put the vehicle in gear and. To use the leakdown tester youll need an air compressor with an air tank. This video is about how to use a harbor freight leak down tester on a small engine. A cylinder leak down test requires the removal of all the spark plugs.

How to use a leak down tester tool cylinder head leakage detector duration. How to perform a leak down test. The process is simple enough pump a measured amount of air pressure. Compressed air 80 to 90 psi is then fed into the cylinder. Remove the spark plugs and rotate the engine to put the cylinder to be tested at tdc. The crankshaft is then turned so that each piston is at top dead centre.

Plug the air line into the tester then use the yellow adjustment knob to change the airflow till the needle on the left gauge is on 100. Today its common practice to use a cylinder leakdown gauge to evaluate how well each cylinder performs in retaining pressure. Chocks behind the wheels can also be useful. Remove the screwdriver and hook the leak down test tool into the spark plug hole. When the leak down test tool is attached to the cylinder the next task is to attach the tool itself to the air compressor. Record leakage percentage for the cylinder.

Place the car into gear if you can but also engage the parking brake so it wont roll. Step 1. Online auto parts 6637 views. Use the leak down test to know if you should be changing head gaskets valves piston rings or looking for a crack.