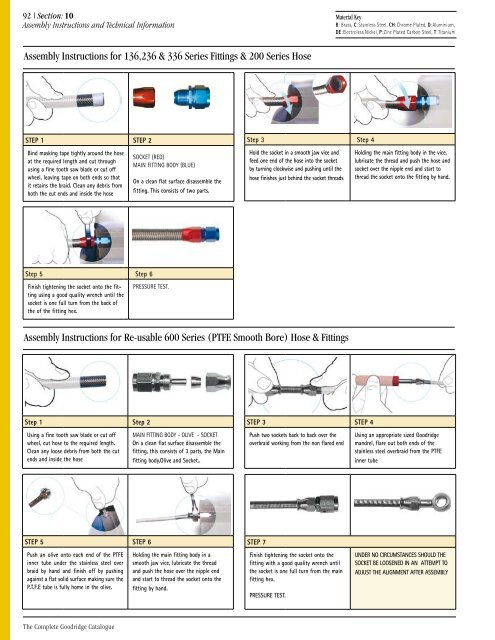

Flexfit hose now offers a ptfe hose assembly program for your on site fabrication shop. Cut the hose squarely to length using a cut off machine or a very fine tooth hacksaw.

Ask Away With Jeff Smith How To Build A Custom Fuel Line

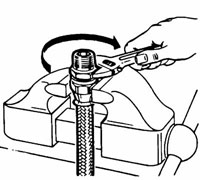

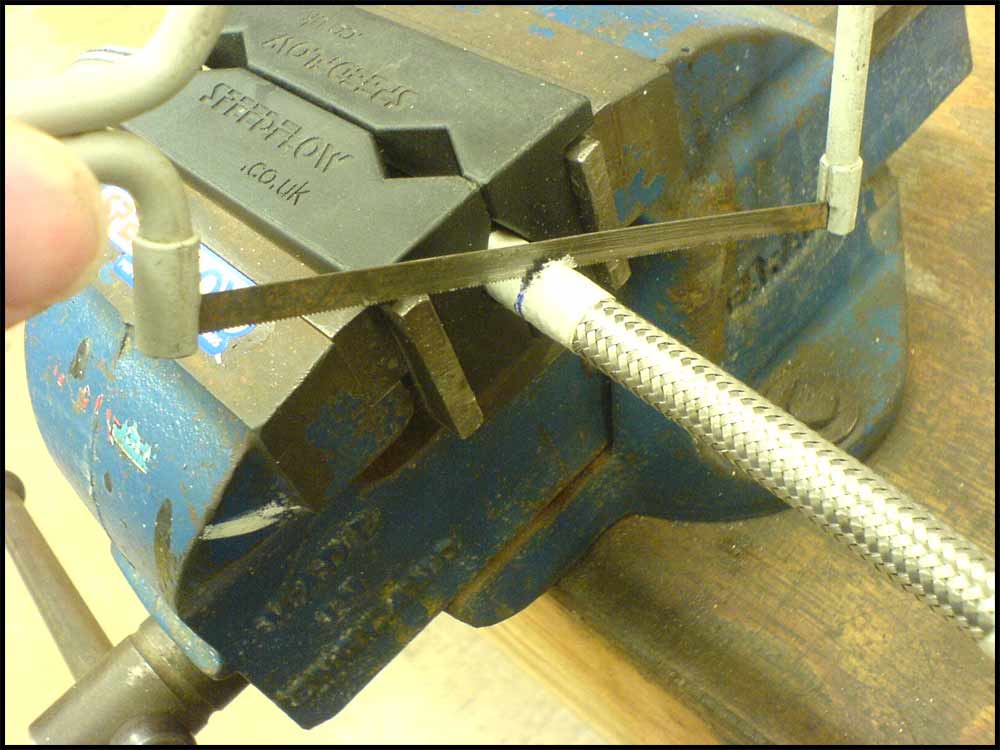

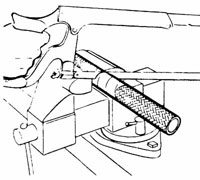

Ptfe hose assembly instructions. Figure 1 12 using a sharp box cutter cut the hose at the location you marked using the ptfe tape. Insert the ptfe hose fitting into the ptfe hose by holding the hose and pushing the hose end nipple into the tube with a combined twisting pushing action. A guide to illustrate practices commonly used throughout the industry. Install ptfe hose assembly on vehicle positioninstall the new techafx blackwrap ptfe an hose assembly on the vehicle once the hose ends are clocked the way you want them to go use two. Wrap hose with glass filament strapping tape at cut off point. Step 6 hold the socket nut in the vice jaws and keeping the assembly square start to engage the socket and ptfe hose fitting thread.

11 in order to prep the hose for assembly it must be cut to length with ptfe thread tape wrapped around the cut location to prevent the polyester braids from excessive fraying. Check it is in as far as it will go. Assembly instructions for 919 ptfe high heat hose fittings 10using a tapered punch push punch into end of sleeve and tube to set sleeve barbs into tube. Hose assembly fabrication guide. Including bulk hose hose fittings crimp collars and an approved crimper. Reusable hose ends for size 4 ptfe hose assembly instructions for braided ptfe racing hose with reusable hose ends these hoses are constructed with the proper lengths hose ends and adapters to allow easy retro fitting on a spec racer.

A step by step illustrated guide on how to put together a hose assembly. Hose assembly instructions ptfe lined brake hose. Brake line kit. Hose assembly instructions. Burrs on bore of tube should be removed with a knife. Everything about metrics.

Remove tape and trim loose wires flush with tube. Kinking of hose occurs more easily in larger sizes and in very short assemblies. Dragging hose on ground surfaces using them as climbing handles and severe bending to fit cramped storage areas must be avoided. We provide provide all components and procedures necessary for you to assemble your hoses on site. Using sae 20 weight lubricating oil lubricate nipple and socket threads. All hose assemblies whether rubber or ptfe should always be handled with care to prevent excessive bending twisting and kinking.

Purchase high quality hose and fittings at great prices for us made components. Do not use duct tape or any other adhesive industrial tape.