Half moon wrench right. To recalculate your torque wrench when using the motion pro adapter use the extension formula included with.

Calculations For Torque Wrench Extension Adapters And Spanners

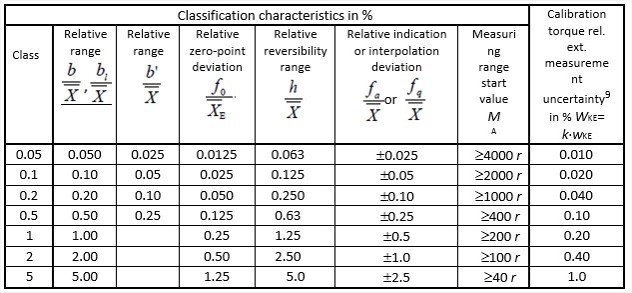

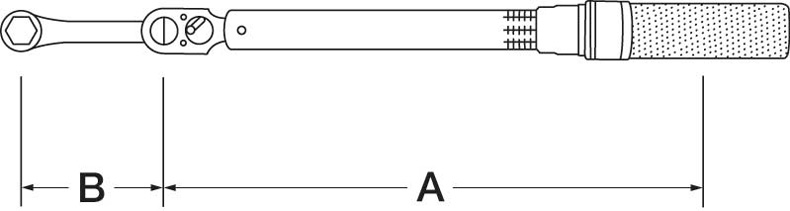

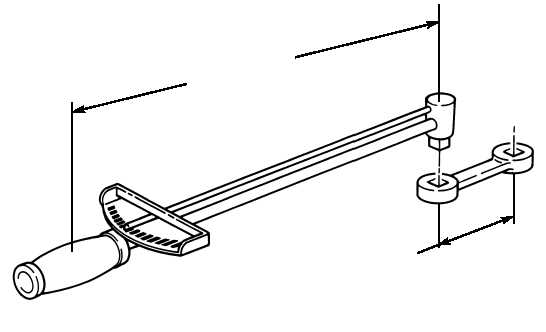

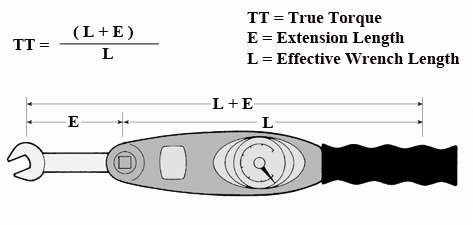

Torque wrench adapter formula. Lbft foot poundslbin inch poundsnm newton meters step 2. Torque wrench adapter formulas. When using extension adapters and spanners the torque applied to the fastener is greater than that preset torque setting or the torque value displayed on the tool. Setting torque wrench length x torque desired torque wrench length adapter extension length step 1. Length of adapter 2. The torque setting on the wrench allowing for the added length of the adapter.

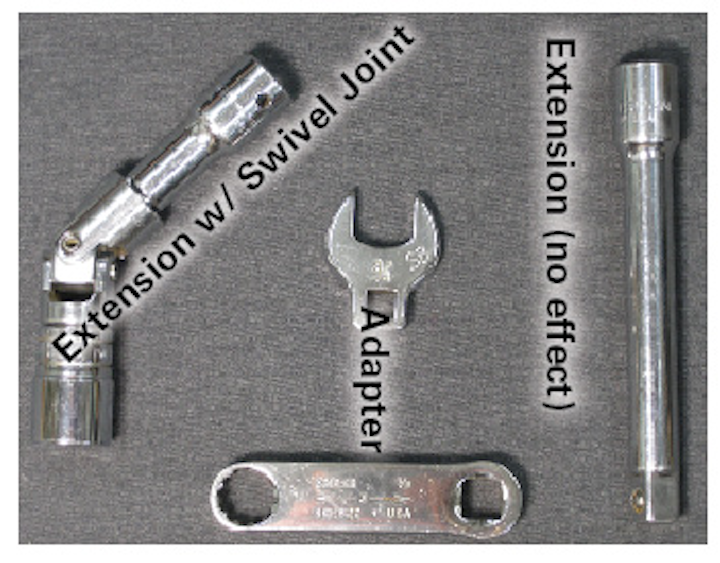

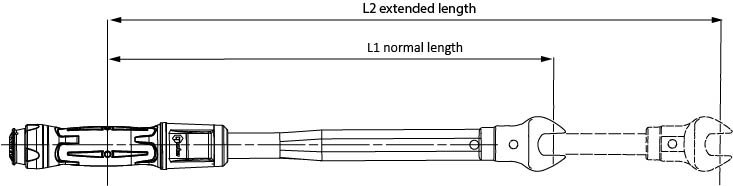

This reading will be lower than the desired torque. Enter fastener torque specification from workshop manual. 1 torque wrench adapters extensions are used to tighten screws and nuts to specific values that cannot be reached with a regular socket on the end of a torque wrench. Torque wrench adapters and conversion formula. Torque wrench adapter extended equations calculator. Measure from center of torque wrench adapter drive to center of tool extension adapter this is e.

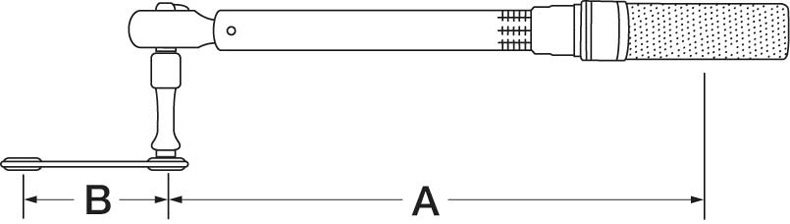

Dial wrench using a 2 long crowfoot adapter. Torque wrench adapter formulas. Desired torque 250 ft. Before using the torque adapter you must recalculate the torque specification listed in the engines service manual. Enter length of torque wrench a instructions. New setting tw.

T target or actual torque required lb in y torque setting or reading to obtain desired torque t in lbs l distance between applied force and torque wrench drive center in e distance between torque wrench drive center and crows foot drive center in. Measure your torque wrench from center of adapter drive to where you will apply force center of hand location this is l. Therefore the torque value set on the torque wrench will not be the actual torque that you apply to the fastener. Half moon wrench left. Measure from center of handle to center of drive. Determine the adapter extension length or offset of fastener to torque wrench by measuring the distance between the following centers.

L effective length. The length of the torque adapter in this example is 3 inches. This makes the dial or scale reading less than the actual torque applied to the screw or nut. To calculate the true torque for the fastening application use this formula. 15 degree wobble extension.